http://www.mcmaster.com/#55835k34/=q4lpi9

See Part 1 of the cable upgrade for more links on the cables & chains.

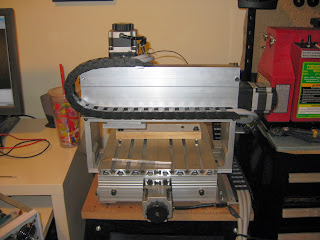

All of the bends were tight with the cable, but don't strain the steppers, or impede movement.

There is a slight problem with the power cable for the spindle motor. Since it moves up and down, there needs to be a certain amount of slack in the wires. I had to add (after this photo was taken) about 3-4" of wire to give it the necessary range of movement. Technically there should also be some kind of cable chain to serve the motor, but on a CNC this small, it's hard to find anywhere to mount it that doesn't interfere.

All axes hooked up the the control box with the next connectors and shielded cables.

Limit switches are probably going to be my next project.